Textile Ducts in Warehouses and High Storage Halls

In these types of facilities, it is crucial to maintain stable conditions throughout the entire volume, including spaces between racks. Textile ducts perform exceptionally well because they:

-

Distribute air evenly – reaching even hard-to-access spaces between racks.

-

Eliminate drafts – important for employee safety and product protection.

-

Are lightweight and flexible – do not overload the roof structure and can be easily adapted to the hall layout.

-

Lower investment and operating costs – using textile ventilation solutions can reduce overall expenses.

Key considerations when designing:

-

Proper duct placement relative to racks

-

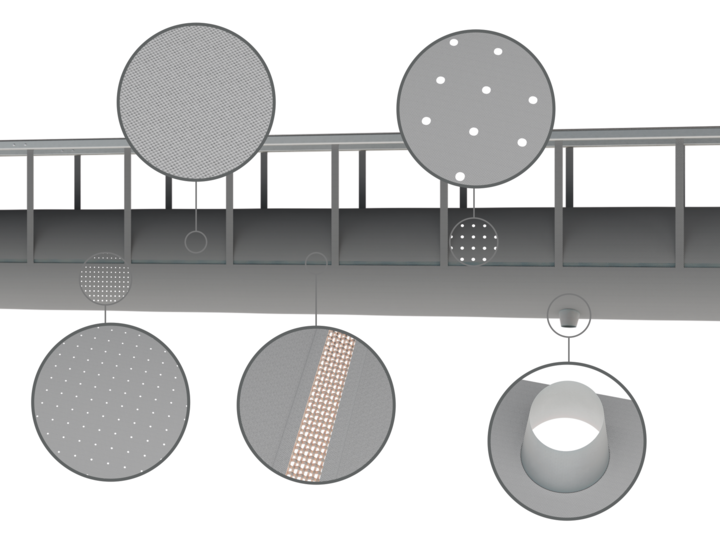

Choice of air supply system (e.g., directional nozzles)

-

Appropriate fabric selection (e.g., SealTex)

For highly suspended ducts, long-range nozzles like UltraVent are recommended. They can increase air velocity from the duct nearly threefold compared to standard perforation.

Long-range nozzles work best with non-permeable fabrics like SealTex, where 100% of the air is directed to the nozzles, resulting in longer throw distances and precise air delivery to critical zones.